Build Better / Low Pitch & Skillion Roofs

How to avoid condensation in low pitch or skillion roofs

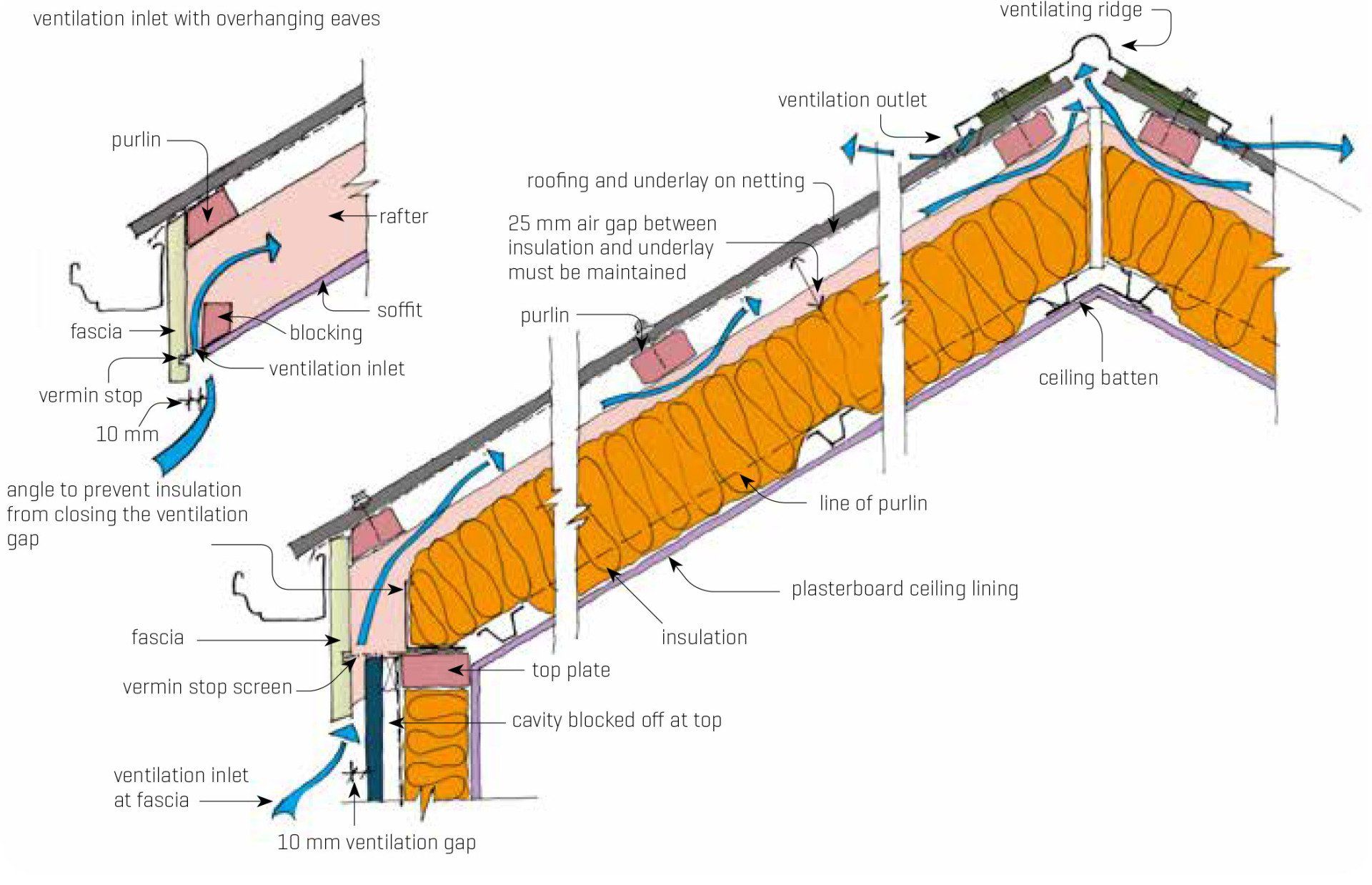

Installing more ventilation and modern underlays will help to prevent moisture and mould damage in homes with a low pitch roof design. There are other types of roofs that are assisted by this type of ventilation such as a skillion roof. It’s particularly important in today’s thermally sealed buildings. This article provides a brief explanation of the associated challenges and potential solutions.

Low pitch roof designs and ceiling air barriers

The energy efficiency of modern homes has made managing condensation in the living spaces beneath a low pitch an essential design consideration. Gone are the cracks and gaps of old that enabled drafts to carry moisture to the outside. These days, moisture added to the living airspace by breathing, cooking, showering and some forms of heating is absorbed and released into the space beneath the roof by permeable ceiling materials, such as plywood and wallboard. It also finds its way into the ceiling cavity through any gaps around light fittings and joins between materials.

Both moisture transfer and the loss of warm air in winter can be avoided by using a vapour-permeable underlay. The resulting air barrier prevents thermal loss, while the vapour transfer helps to keep living spaces drier and healthier.

Specifying and installing a ceiling air barrier in low pitch and skillion roof designs

The air barrier standards for low pitch or skillion roofs specified by BRANZ provide a guide to selecting a suitable vapour permeable underlay for controlling this air transfer in buildings with a low pitch roof. Choosing a wide underlay, such as Covertek 407, can improve installation efficiency by reducing the required taping of underlay joints.

A vapour barrier may be required for some ceilings

In situations that could lead to high roof cavity condensation, some designs may require a ceiling barrier that prevents vapour from the living spaces entering the roof cavity at all. Examples include buildings with sauna or spa bath wet rooms, and those in cold climate zones that are likely to experience snow or heavy frosts on the roof.

Where these conditions apply, Thermakraft recommends a suitable ceiling barrier for reducing the level of water vapour reaching the roof cavity from living spaces.

Low pitch roof designs have limited roof cavity air space

Low pitch roof designs don’t have the large air space and free air movement found in attics of more traditional building designs. This increases the potential for condensation to build up and support the growth of damaging and unhealthy mould.

Ventilation in a low pitch or skillion roof cavity

The limited natural air flow in a low pitch or skillion roof design can be overcome by installing appropriate ventilation systems. The most suitable ventilation will depend on the roof design and may include options such as ridge ventilation, under-eave apertures, and ventilation battens or channels.

Low pitch or skillion roof cladding underlays

The cladding under roofing material provides a second barrier to water entering the building through the roof. Like the roofing material, it will also cool as outside temperatures drop, particularly at night. This leads to condensation forming on the underlay, which makes it damp. The moisture is released again as water vapour when its temperature rises, typically during the day. Modern permeable and absorbent synthetic underlays, such as Covertek 407, are engineered to optimise water retention until increasing temperatures release it as vapour to be expelled by suitably-designed ventilation.

More information

High-tech synthetic underlays have greatly enhanced condensation management, but they’re only part of the story. To learn more, see our

guide to moisture management.

Can't find what you are looking for?

Get in touch, our team is always ready to help.

Products/Technical Information

Build Better

Location

© 2021 Thermakraft Australia PTY Ltd

All Rights Reserved

Kingspan PTY Limited | All Rights Reserved