Build Better / Vapour Permeable vs Foil

Why choose vapour-permeable wrap instead of foil

How a vapour-permeable wrap beats foil

In 2019, the National Construction Code (NCC) was updated to require vapour-permeable membrane wraps on all new-builds in climate zones 6, 7 and 8. It was in response to evidence that building integrity and personal health issues, such as rot and mould, were being caused by hidden internal condensation. While foil wraps had helped to keep water out for decades, they prevented harmful water vapour inside wall and roof cavities from escaping to the outside.

No matter what climate zone you’re operating in, specifying and installing a vapour-permeable wrap will help you to construct a drier, safer and healthier building. It’s about doing the right thing, whether it’s mandated for your climate zone or not. Before we explain the differences between breathable and vapour-permeable materials, let’s consider why we’re hearing these terms so much these days. In our opinion, it’s a reaction to a couple of problems the residential construction industry has been experiencing in recent times.

How does a vapour-permeable wrap or underlay work?

The drive to create more energy-efficient buildings has led us to almost airtight construction. Things like cooking, showering and simply breathing add water vapour to the air inside a building. In fact, a family of four typically produces 20 litres of water a day into their home.

Once released into the air, water vapour naturally spreads from areas of high concentration to low. Warmer air has a higher capacity to hold water vapour. When it reaches cooler air, such as that alongside cold surfaces, some of the vapour condenses back to liquid water. This is most often observed on bathroom mirrors and the inside of windows cooled by an overnight drop in the outside temperature.

A less-visible site of condensation is the inside surface of a building’s outermost layers, such as a foil underlay. Here, beyond the internal cladding and thermal insulation, the water vapour is trapped and cools. This creates the liquid condensation that sustains unhealthy moulds and mildew, and rots or rusts framing. In addition, as the water vapour condenses to liquid water, its concentration in the air reduces, encouraging more water vapour to move towards the cooling surface.

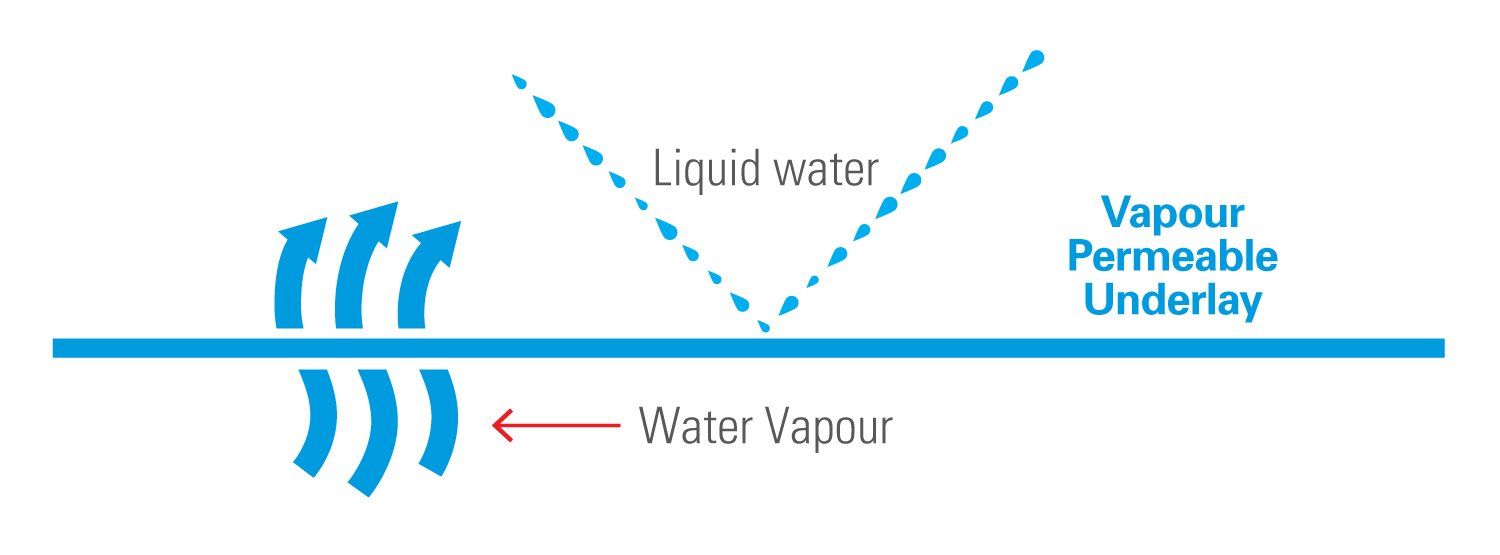

A vapour-permeable wrap or underlay, such as Covertek 407 by Thermakraft, uses technology that allows water vapour to pass through it to the outside. At the same time, when correctly installed, it is impermeable to liquid water, air, and dust in either direction. It effectively provides a barrier for everything except the exiting water vapour.

Is a perforated foil the same as a vapour-permeable membrane underlay?

Often referred to as ‘breather products’, some building wraps or cladding underlays were created by putting lots of tiny holes (perforating) traditional impermeable barriers, such as foil. The idea was to create a product that allowed some air and water vapour to pass through it. However, to maintain a liquid water barrier, the holes can only be pin-sized. In addition, the holes allow air to pass through in both directions, so they provide opportunity for warm air to escape in winter and moist air to enter the building from the outside.

Engineered vapour-permeable membranes allow water vapour to pass through them much more quickly than perforated foil products. They also remain completely impermeable to air, dust and liquid water. When applied over soggy wooden framing for example, synthetic vapour-permeable wraps have been shown to have a significantly higher drying rate than a perforated wrap.

In short, perforated breather products are an adaption of traditional impermeable underlays. Vapour-permeable wraps, on the other hand, are purpose-built using advanced synthetic materials that allow water vapour to escape with remarkable efficiency.

A modern technology that’s finding many uses

Similar technology is used in other applications, such as modern outdoor work gear and mountaineering, snow sport and sailing clothing. They’re sometimes called breathable or wicking fabrics because of the way they draw moisture from the inside to the outside. You may have heard the brand Gore-Tex, for example. The garments they make are wind-proof and water-proof, and they can retain body heat while allowing water vapour from perspiration to easily escape. No matter how active the wearers are, they remain dry and comfortable, just like the inside of a building should be. Can you imagine working out or simply spending your days permanently wrapped in foil?

The NCC sets the minimum required standard

If you’re building in climate zones 6, 7 and 8 you have to use a vapour-permeable wrap. From Coffs Harbour around to Adelaide, Esperance to Bunbury and all of Tasmania, it’s a must. Throughout the rest of Australia, many specifiers and builders who understand the technology still insist on vapour-permeable membrane wrap, not because they have to but because they want to construct quality buildings.

Those who always specify vapour-permeable wrap recognise that any moisture trapped during construction, or water vapour entering cavities during the building’s lifetime, will be quickly expelled to the outside. It’s not a cosmetic thing; it’s lasting protection deep within the structure of the building. And it’s a concept that building and home owners find easy to understand, which helps and more than justifies any extra expense. Beyond living in a drier, safer and healthier building, they get a construction that will last longer.

Can't find what you are looking for?

Get in touch, our team is always ready to help.

Products/Technical Information

Build Better

Location

© 2021 Thermakraft Australia PTY Ltd

All Rights Reserved

Kingspan PTY Limited | All Rights Reserved